Symbiose: Vlaamse bedrijven wisselen reststromen uit

De OVAM ondersteunt het symbioseplatform, omdat symbiose leidt tot gesloten materiaalkringlopen. Zo vermindert u de hoeveelheid bedrijfsafval en valoriseren we waardevolle reststromen.

Hoe werkt het?

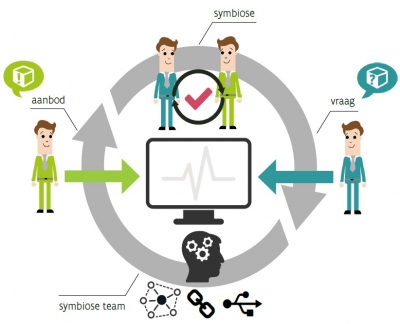

Hoe werkt het?Op het platform vindt u een databank aan vragen en aanbiedingen. U kan daarin materialen opzoeken. Denk aan reststromen, recyclaten of alternatieve grondstoffen die u in uw bedrijf kan inzetten. Of u kan nagaan welke bedrijven op zoek zijn naar een materiaal dat in uw bedrijf als reststroom vrijkomt.

Hebt u interesse in een bepaalde vraag of aanbod? Dan kan u op het platform contact opnemen met het bedrijf waarmee u een samenwerking wil starten. Zonder enige verplichting. De aanbieder of vrager van dat materiaal kiest zelf wanneer het zijn identiteit en detailinformatie deelt.

Ondernemingen bepalen de details van een symbiose-overeenkomst volledig autonoom. Ook de financiële component.

Doe een beroep op het symbioseteam wanneer u een vraag hebt. Zij bieden hulp en expertise over praktische, technologische, logistieke en juridische zaken. Het symbioseteam is een ervaren team, dat onafhankelijk van de OVAM werkt.

De OVAM ondersteunt deze hoogwaardige materiaalvalorisatie bij bedrijven zodat zij meer materiaalkringlopen kunnen sluiten en minder (primaire) materialen verspillen. De OVAM heeft evenwel geen zicht op de individuele bedrijfsdata binnen het online platform, deze zijn enkel zichtbaar voor het Symbioseteam. De OVAM gebruikt enkel de geaggregeerde symbiosedata in haar beleidsmonitoring van de circulaire economie.

Meer weten? Lees onze antwoorden op de veelgestelde vragen of contacteer info@smartsymbiose.com.

Onze garanties:

- U ontvangt gratis hulp en expertise van een ervaren symbioseteam, zowel over technologische, logistieke als juridische zaken.

- U bepaalt altijd zelf met wie u uw informatie deelt.

- Uw samenwerkingen zijn een economische meerwaarde: u kunt uw afvalkost omzetten in een materiaalopbrengst.

- De milieu-impact van uw bedrijf gaat omlaag.

- U vergroot uw kennisnetwerk.

Het Symbiose-project startte in september 2012 en werd gesubsidieerd door het Agentschap Innoveren en Ondernemen tot en met december 2015. Catalisti maakte actief deel uit van de uitvoering van het project van september 2014 tot december 2015.