ESSSC-project: Request for Industrial Partners

Electrochemical syngas by co-electrolysis of H₂O and CO₂ using versatile SOEC technology for steel making and chemical industry. ESSSC-project: Request for Industrial Partners.

Introduction

Syngas, a mixture of carbon monoxide (CO) and hydrogen (H₂), is an indispensable feed gas in the chemical industry. It can be transformed into valuable hydrocarbon products, such as fuels, methanol, and olefins. Currently, fossil resources, including coal and natural gas are used to produce syngas. The pressing visibility of climate change effects, coupled with the escalating regulations on carbon emissions, necessitates urgent actions to strive towards more sustainable processes.

Electrification of the chemical industry offers a compelling chance to improve its climate impact. The swiftly dropping costs of renewable energy create an appealing opportunity to propel the chemistry sector toward sustainability. More specifically, the electrification of syngas production by relying on renewable energy would not only transform industry norms but also contribute to a reduction in carbon dioxide (CO₂) emissions and save valuable emission rights.

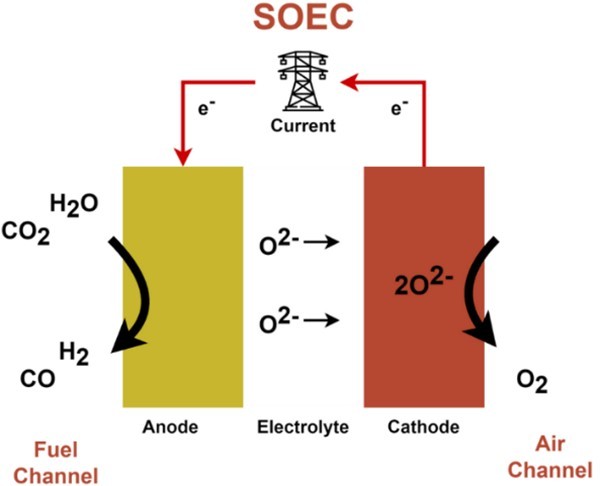

In this context, Solid Oxide Electrolysis Cells (SOEC) emerge as a promising technology for electrical syngas production by co-electrolysis of water and CO₂ (Figure). This oxygen anion-based solid oxide technology utilizes CO₂ as a feedstock to produce syngas with a versatile CO/H₂ range. The unparalleled efficiency of SOEC makes it an attractive solution, particularly when waste heat or steam is available.

Goals

The ESSSC project seeks to leverage SOEC technology to electrify syngas production through the co-electrolysis of H₂O and CO₂. This cutting-edge initiative aims to advance beyond current industry standards by achieving the following objectives:

- To develop a Ni-free SOEC stack with enhanced sulfur resistance, allowing direct treatment of impure feed gases (e.g., blast furnace gas).

- Achieving high CO₂ conversion rates (up to 99%), eliminating the need for expensive post-processing purification steps.

- Generate a wide range of CO/H₂ ratios due to the unique gas distribution method.

-

Easy dismantling at end-of-life: The SOEC stack will be designed for circularity, enabling easy disassembling and recyclability.

- Unlocking the vast potential of H₂ and CO as pivotal molecules for green chemistry within the chemical industry.

This significant amount of CO₂ the steel industry emits can be used as a direct feed gas for electrochemical syngas production using SOEC. Hence, the ESSSC project aims to demonstrate the production of syngas from blast furnace gas by employing SOEC technology. A pilot SOEC system will be developed, including a 30 kW electrolyzer capable of processing 10 tonnes of CO₂ per month and converting it into syngas.

To further expand the project's impact, the consortium is actively seeking a strategic partnership with a chemical company keen on incorporating electrical syngas as a feedstock. Additionally, the consortium is seeking companies with significant CO₂ emissions that are interested in implementing the SOEC technology. This collaboration presents an exceptional opportunity to collaborate with the industrial (VIRECA and ArcelorMittal) and academic partners (UGent) in this project.

Request

To complete the consortium, Catalisti is searching for additional industrial partners to use the developed technology within the chemical industry. Specifically, the consortium is seeking industrial partners who (i) have expertise in syngas usage, or (ii) have significant CO₂ emissions and are eager to implement SOEC technology in their processes.

How to reply to this request?

Please send an email to Dieter Ruijten (druijten catalisti.be (druijten[at]catalisti[dot]be)) with Stef Koelewijn (skoelewijn

catalisti.be (druijten[at]catalisti[dot]be)) with Stef Koelewijn (skoelewijn catalisti.be (skoelewijn[at]catalisti[dot]be)) in cc, and briefly describe your interest and potential contribution to the project, before 23 August 2024. Based on all offers, the current industrial partners will determine together with Catalisti which partners can join the consortium. After submission of your offer, you can be contacted to further elaborate your offer.

catalisti.be (skoelewijn[at]catalisti[dot]be)) in cc, and briefly describe your interest and potential contribution to the project, before 23 August 2024. Based on all offers, the current industrial partners will determine together with Catalisti which partners can join the consortium. After submission of your offer, you can be contacted to further elaborate your offer.

Important notice

Partners that wish to participate in Catalisti-supported projects are required to be member of Catalisti. For more information on membership and membership fees, please visit our website or contact Dieter Ruijten (druijten catalisti.be (druijten[at]catalisti[dot]be)) with Stef Koelewijn (skoelewijn

catalisti.be (druijten[at]catalisti[dot]be)) with Stef Koelewijn (skoelewijn catalisti.be (skoelewijn[at]catalisti[dot]be)) in cc.

catalisti.be (skoelewijn[at]catalisti[dot]be)) in cc.